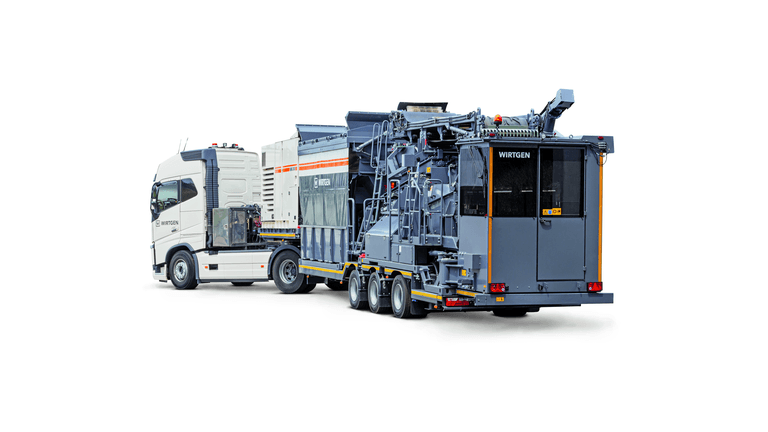

WIRTGEN KMA 240i

Mobile Cold Recycling Mixing Plant

Equipment Specifications

| SPECIFICATIONS - Feeding height (average) | 11 ft 10 in |

|---|---|

| SPECIFICATIONS - Length excluding cabin / including cabin | 49 ft 3 in / 49 ft 3 in |

| SPECIFICATIONS - Height, in. | 1 in |

| SPECIFICATIONS - Width | 8 ft 2 in |

| SPECIFICATIONS - Width, ft. | 8 ft |

| SPECIFICATIONS - Design | Twin-shaft pugmill |

| SPECIFICATIONS - Exhaust emissions category | EU Stage 5/US EPA Tier 4f |

|---|---|

| SPECIFICATIONS - Width, in. | 2 in |

| SPECIFICATIONS - Mixing performance | 265 t/hr |

| SPECIFICATIONS - Feeding width | 12 ft 2 in |

| SPECIFICATIONS - Height, ft. | 13 ft |

| SPECIFICATIONS - Operating weight, CE | 70.217 lbs |

| SPECIFICATIONS - Operating principle | Continuous mixer |

| SPECIFICATIONS - Height | 13 ft 1 in |

| SPECIFICATIONS - Max. particle size | 1.8 in |

| SPECIFICATIONS - Power | 129 kW / 173 hp |

| SPECIFICATIONS - Displacement | 370 in³ |

Featured Content

Cold recycling can either be carried out in-plant by transporting the material recovered from an existing road to a central warehouse and passing it through a mixing plant, or in-place/in-situ using a cold recycler.

In the in-place/in-situ mixing process, a cold recycler granulates the existing pavement and homogeneously mixes in the binding agent and water.

In the in-plant mixing process, RAP and crushed rock are transported to a mixing plant near the construction site.

The KMA 220/KMA 220i is mounted on a flatbed semitrailer and has its own motor station. This mobile design allows the system to be quickly moved to different locations and set up rapidly. Wheel loaders pour a wide variety of unbound raw materials into the proportioning hopper via vibrating grates. Silos or tank trucks supply the plant with binding agents such as cement, bitumen emulsion, or foamed bitumen. A microprocessor-controlled plant control system monitors the addition of raw materials and binding agents into the mixing chamber for high-precision dosing. Here, a heavy-duty twin-shaft pugmill produces a high-quality, homogeneous mix. Finally, the finished mix is smoothly loaded onto the swivel-mounted conveyor, which makes it possible to completely fill even long semitrailers.

All WIRTGEN machines feature a built-in, high-quality machine control system. The fact that the majority of its software is developed in-house plays a key role in this regard – WIRTGEN has placed a special focus on ongoing development, thus significantly increasing the operational reliability of its machines. Many years of experience in software and hardware development also makes it possible to achieve more flexible and sophisticated machine functionality in terms of the range of applications and individual customer requirements.

Effective and environmentally friendly mix preparation

-

The KMA 240i high-performance cold recycling mixing plant is designed for the resource-friendly production of high-quality mix at a massive mixing capacity of more than 265 t (240 tons) per hour.

-

The KMA 240i is capable of processing a wide variety of base materials, such as recycled construction materials, milled asphalt material, demolished concrete, or virgin road construction materials, as well as binding agents, such as cement, bitumen emulsion, or foamed bitumen.

-

The mix is ideally suited for any type of construction project, e.g. for cement-treated or long-lasting bituminous base layers in road and path construction, parking lots, and industrial areas.

-

The mobile design of the cold recycling mixing plant allows the machine to be transported directly to the job site, saving both time and money.

-

The ability to completely recycle materials in combination with cold processing results in significant CO2 and energy savings with minimal construction costs and project periods.