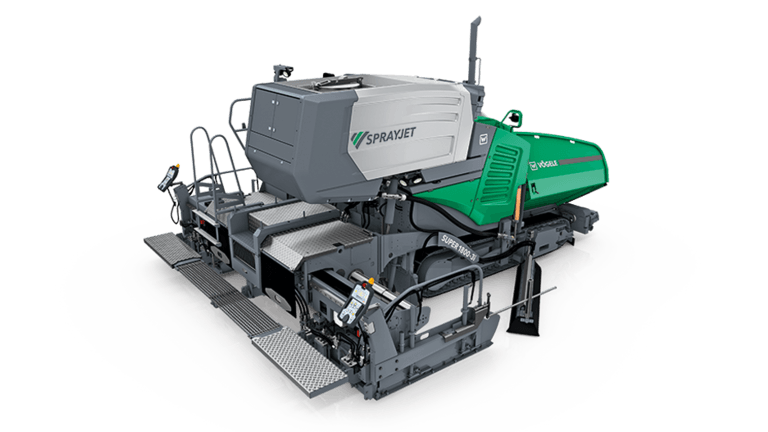

VOGELE SUPER 1800-3i SprayJet

Road Pavers

The unique spray paver with innovative technology

The VÖGELE SUPER 1800-3 SprayJet is the world‘s only spray paver for placing thin asphalt overlay as well as conventional binder and surface courses. The new VÖGELE SprayJet features a large array of impressive innovations. One key feature is that operation of the spray module has been integrated into the ErgoPlus 3 operating concept.

| DRIVE - Daily noise exposure level | 80 dB |

|---|---|

| UNDERCARRIAGE - Track tension adjuster | spring assembly |

| UNDERCARRIAGE - Paving speed (up to) | 79 fpm |

| UNDERCARRIAGE - Lubrication of track rollers | lifetime |

| UNDERCARRIAGE - Version | provided with rubber pads |

| SCREED - Power supply | three-phase AC generator |

| DRIVE - Sound power level | 108 dB |

| UNDERCARRIAGE - Travel speed (up to) | 2.8 mph |

| DRIVE - Manufacturer | Cummins |

| DRIVE - Type | B6.7 - C173 |

| DRIVE - Exhaust emissions after-treatment | DOC, DPF, SCR |

| DRIVE - Nominal output | 173 hp / 2,000 RPM |

| UNDERCARRIAGE - Traction drive crawler tracks | electronically controlled separate hydraulic drive provided for each crawler track |

| SCREED - Screed heating | electric, thermostat-controlled |

| UNDERCARRIAGE - Ground contact | 2,830 mm x 305 mm |

| SCREED - Screed | Type Basic width Maximum width (TV, TP1) Maximum width Compacting systems AB 500 8 ft 4 in 19 ft 8 in TV, TP1 AB 600 9 ft 10 in 19 ft 8 in TV, TP1 VR 600 10 ft 19 ft 8 in V |

| DRIVE - ECO mode output | 173 hp / 1,700 rpm |

| DRIVE - Version | liquid-cooled 6-cylinder diesel engine |

| DRIVE - Exhaust emissions standard | European exhaust emissions standard V, US standard EPA Tier 4f |

| CONVEYORS AND AUGERS - Conveyors | 2 |

| CONVEYORS AND AUGERS - Drive | separate hydraulic drives, proportional control |

| CONVEYORS AND AUGERS - Version | with replaceable feeder bars, direction of conveyor temporarily reversible |

| SPRAYJET MODULE - Number of spray bars | 5 |

| MATERIAL HOPPER - Positions | can be adjusted in a forward direction by 3 in |

| MATERIAL HOPPER - Standard | oscillating |

| SPRAYJET MODULE - Standard | 555 Imp.gal |

| SPRAYJET MODULE - Rate of spread | 0.06 lbs/sq.ft to 0.33 lbs/sq.ft |

| SPRAYJET MODULE - Spray cone | 120 ° |

| CONVEYORS AND AUGERS - Height | infinitely variable |

| DIMENSIONS AND WEIGHTS - Operating weight | Screed Total weight AB 500 TV 49,360 lbs AB 500 TP1 50,130 lbs AB 600 TV 50,290 lbs AB 600 TP1 51,060 lbs |

| SPRAYJET MODULE - Emulsion tank | insulated hopper walls |

| DIMENSIONS AND WEIGHTS - Spray width | 8 ft 4 in to19 ft 8 in |

| CONVEYORS AND AUGERS - Lubrication | centralized lubrication system, electrically-driven grease pump |

| SPRAYJET MODULE - Number of spray nozzles | 24 |

| DIMENSIONS AND WEIGHTS - Maximum laydown rate | 770 US t/hr |

| SPRAYJET MODULE - Spray pressure (up to) | 43.6 psi |

| DIMENSIONS AND WEIGHTS - Length | Screed Total length AB 500/AB 600 TV 19 ft 10 in AB 500/AB 600 TP 20 ft 3 in |

| CONVEYORS AND AUGERS - Version | with replaceable auger blades, reversible direction of rotation |

| CONVEYORS AND AUGERS - Speed | 84 rpm |

| CONVEYORS AND AUGERS - Standard height | hydraulically adjustable by 6 in |

| SPRAYJET MODULE - Optionally with extra tank | 1,876 Imp.gal |

Featured Content

The philosophy behind the machine concept of the Premium Line road pavers is “Lower consumption – lower emissions – lower costs”. The VÖGELE EcoPlus low-emissions package combines a number of individual measures to reduce the fuel consumption and noise levels to a significant extent.

VÖGELE Niveltronic Plus Automated Grade and Slope Control is a unique grade and slope control system providing the basis for efficient paving true to line and level on any kind of base. Niveltronic is an in-house development by VÖGELE and is based on many years’ experience in grade and slope control technology. In terms of ease of operation, quality and reliability, Niveltronic Plus represents the perfect solution for all grade and slope control tasks.

VÖGELE’s SprayJet technology has proved its value for many years and is used for pavement rehabilitation and construction in markets around the world.

Even the very best machine with the most advanced technology can only really show its strengths if it can be operated easily and as intuitively as possible. At the same time, it should offer an ergonomic and safe working environment for the operating team. Therefore, the ErgoPlus 3 operating concept focuses on the operator.