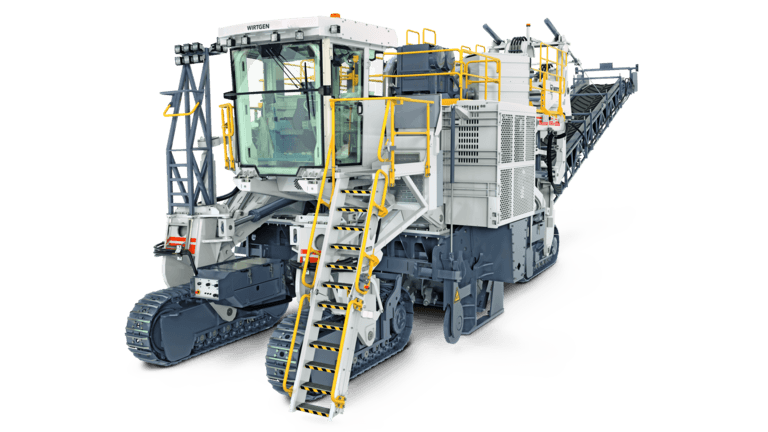

WIRTGEN 4200 SMi

Surface Miner

Equipment Specifications

| SPECIFICATIONS - Exhaust emissions category | EU not rated/US EPA Tier 4f |

|---|---|

| SPECIFICATIONS - Operating weight, CE | 450,397 lbs |

| SPECIFICATIONS - Cutting width max. | 13 ft 9 in |

| SPECIFICATIONS - Max. travel speed | 0 - 1.6 mph |

| SPECIFICATIONS - Power | 1,194 kW / 1,600 hp |

| SPECIFICATIONS - Max. working speed | 0 - 89 ft / min |

| SPECIFICATIONS - Cutting depth | 32 in |

|---|

Featured Content

High quality results are the goal of every construction project. This applies to road rehabilitation using cold milling machines and cold recyclers as well as to soil stabilization and the extraction of minerals with surface miners. In order to remove pavement with precision and efficiency, it is essential that the drum, pick holder, and pick work together perfectly.

WIRTGEN is the market leader in cutting technology and offers customers high-performance cutting systems whose components are designed to be fully compatible. In addition, WIRTGEN continuously makes advancements to these cutting technology components, incorporating its practical experience and feedback from customers into the process.

WIRTGEN’s leveling technology adjusts height, depth, and pitch for extremely accurate results. In the process, the system permanently compares the actual values to predefined target values and adjusts the deviations proportionally. This state-of-the-art machine technology consistently guarantees outstanding leveling results and significantly reduces the machine operator’s workload.

WIRTGEN offers customers reliable hardware and software developed in-house. In this context, a variety of systems are used depending on the construction project and local conditions at the job site.

As the surface miner moves forward, a special cutting drum rotates against the direction of travel, cutting layers of material from the rock formations and crushing it in the process. The primary conveyor picks up the material in the drum housing and transports it towards the rear of the machine, where it is then accepted by the slewable and height-adjustable discharge conveyor. The discharge conveyor loads the material into trucks or dumpers or discharges it to the side of the miner. The discharge height can be adjusted to the height of the transport vehicles. The surface miner is driven via four steerable and height-adjustable track units. An automatic leveling system ensures precise adherence to the cutting depth, thus enabling even thin seams or layers to be mined selectively and with maximum accuracy.

Maximum performance in large-scale opencast mining

-

Surface miner with maximum mining performance for selective mining of hard or soft rock.

-

The 4.2 m cutting drum unit with a cutting depth of up to 650 mm in hard rock, which is precisely adapted to the specific application, achieves outstanding cutting performance with minimal cutting tool wear.

-

The powerful rear loading conveyor can be elevated and rotated and makes it possible to load trucks with a payload of 120 to 220 tons.

-

With an annual production capacity of up to 12 million tons in soft rock, the miner is ideally suited for large-scale open-cast mining.

-

The operator’s cabin features windows on all sides and is heatable, air-conditioned, soundproofed and isolated from vibrations for fatigue-free, productive work.