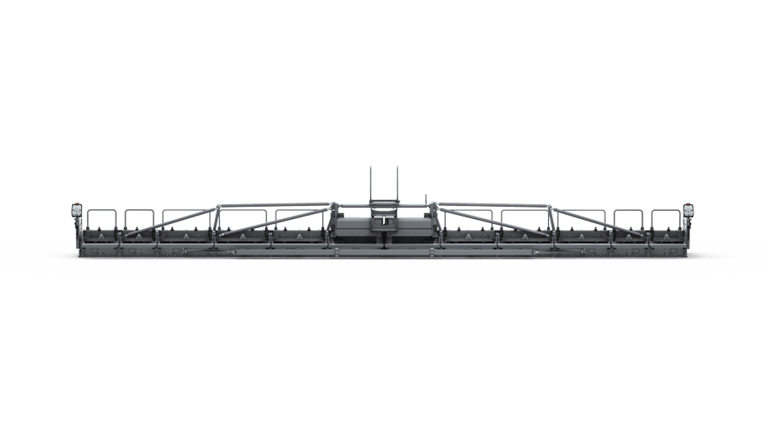

VOGELE SB 300

Fixed-Width Screeds

The specialist in jointless paving

Fixed-width screeds from VÖGELE deliver absolutely high-quality, perfectly even results. Their strengths come to the fore when laying down asphalt across pave large widths and thick base courses. The SB 300 Fixed-Width Screed offers a wide range of applications, covering pave widths of 3m to 16m and layer thicknesses of up to 50cm, depending on the tractor unit.

| COMPACTING SYSTEMS - Vibrators (V) | eccentric vibrators |

|---|---|

| COMPACTING SYSTEMS - Stroke, optional hydraulic (TV, TP1, TP2) | 0.16 in, 0.31 in |

| SCREED HEATING - Output generation | three-phase AC generator |

| COMPACTING SYSTEMS - Pressure bar drive (P) | pulsed hydraulic |

| PAVING WIDTHS - Maximum paving width | 52 ft 6 in |

| DIMENSIONS AND WEIGHTS - Depth (in transport position) | Screed Depth SB 300 4 ft 5 in |

| PAVING WIDTHS - Bolt-on extensions, hydraulically adjustable | 4 ft 1 in |

| COMPACTING SYSTEMS - Stroke, standard (TV, TP1, TP2) | 0.08 in, 0.16 in, 0.28 in |

| DIMENSIONS AND WEIGHTS - Weight of basic screed | Screed Weight SB 300 TV 5,180 lbs SB 300 TP1 5,510 lbs SB 300 TP2 5,840 lbs |

| SCREED HEATING - Heating rods | on screed plates and in tamper bars and pressure bars |

| COMPACTING SYSTEMS - Pressure bar pulse frequency (P) (max.) | 68 Hz |

| COMPACTING SYSTEMS - Frequency (max.) | 50 Hz |

| COMPACTING SYSTEMS - Hydraulic oil pressure (max.) | 1,740 psi |

| SCREED HEATING - Control | fully automatic, thermostat-controlled |

| PAVING WIDTHS - Basic width | 9 ft 10 in |

| COMPACTING SYSTEMS - Speed (max.) | 1,800 rpm |

| PROFILE SETTINGS - Version | mechanical |

| PROFILE SETTINGS - Crown adjustment | -2 % to 3 % |

| COMPACTING SYSTEMS - Compacting systems | TV, TP1, TP2 |

| SCREED HEATING - Optional screed heating | function monitoring of each individual heating rod |

| PAVING WIDTHS - Length | Bolt-on extensions 10 in 20 in 39 in 59 in |

Featured Content

VÖGELE screeds feature leading-edge technology made possible by state-of-the-art production processes. The first of these processes, the precision cutting to shape of extremely wear-resistant sheet steel, takes place on laser cutting stations. Robots which operate continuously to a consistently high standard ensure long-lasting, stable welds.

The pressure bars driven by pulsed-flow hydraulics are the core of VÖGELE high-compaction technology. By combining screed versions TP1, TP2 and TP2 Plus with this unique technology, our pavers achieve maximum compaction values. Compaction performances of over 98% can be achieved with VÖGELE’s unique high-compaction technology – without rolling.

VÖGELE sets the benchmark with products that deliver a phenomenal degree of precompaction in the paving process. Cutting-edge technology and the most advanced materials guarantee the outstanding performance and reliability of VÖGELE compaction technology. This applies to all VÖGELE compacting systems, from vibrators all the way to the VÖGELE high-compaction system with tamper and pressure bars.

VÖGELE has put its faith in electric screed heating for decades. This extensive experience, in combination with continuous further development, means that VÖGELE screeds are now brought to temperature quickly and evenly.