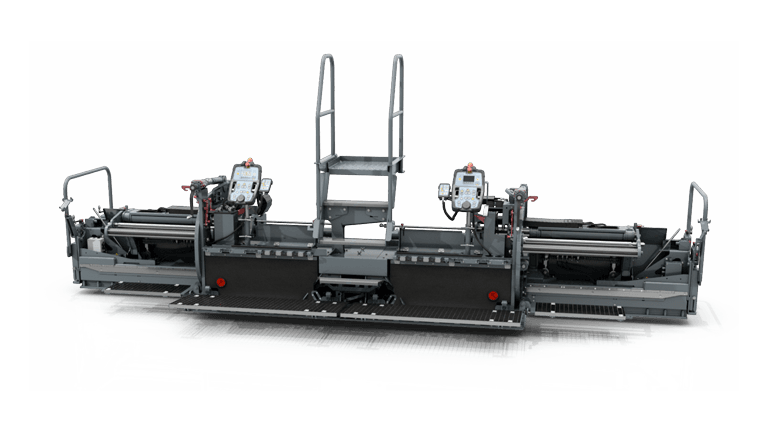

VOGELE VF 600

Extending Screeds

Extending screed with front-mounted extensions for 10-foot pavers

The VF 600 Extending Screed has been specially developed for the SUPER 2000-3i and SUPER 2003-3i pavers of the Highway Class, which feature high paving speeds and different paving widths. The screed‘s sturdy, smoothly sliding telescoping system guarantees precise paving across all widths. In addition, the screed is suitable for a wide range of paving profiles, including crowns and cross slopes.

| SCREED HEATING - Control | fully automatic, thermostat-controlled |

|---|---|

| DIMENSIONS AND WEIGHTS - Width (without end gate) | 10 ft 6 in |

| DIMENSIONS AND WEIGHTS - Depth (in transport position) | Screed Depth VF 600 4 ft |

| PAVING WIDTHS - Hydraulically adjustable | 10 ft to 19 ft 6 in |

| COMPACTING SYSTEMS - Frequency (max.) | 50 Hz |

| SCREED HEATING - Output generation | three-phase AC generator |

| PROFILE SETTINGS - Crown adjustment | -2 % to 5 % |

| PAVING WIDTHS - Cut-off shoes | 4 x 1 ft |

| COMPACTING SYSTEMS - Compacting systems | V |

| PAVING WIDTHS - Length | Bolt-on extensions 12 in 24 in |

| DIMENSIONS AND WEIGHTS - Weight of basic screed | Screed Weight VF 600 7,390 lbs |

| PROFILE SETTINGS - Berms | 12 in, 18 in, 24 in |

| COMPACTING SYSTEMS - Vibrators (V) | eccentric vibrators |

| PAVING WIDTHS - Maximum paving width | 25 ft 5 in |

| PAVING WIDTHS - Basic width | 10 ft |

| SCREED HEATING - Heating rods | on screed plates |

| PAVING WIDTHS - Minimum paving width | 6 ft |

| PROFILE SETTINGS - Version | hydraulic |

| PROFILE SETTINGS - Slope, extending units (max.) | 10 % |

Featured Content

VÖGELE has put its faith in electric screed heating for decades. This extensive experience, in combination with continuous further development, means that VÖGELE screeds are now brought to temperature quickly and evenly.

VÖGELE screeds feature leading-edge technology made possible by state-of-the-art production processes. The first of these processes, the precision cutting to shape of extremely wear-resistant sheet steel, takes place on laser cutting stations. Robots which operate continuously to a consistently high standard ensure long-lasting, stable welds.